SYSTEM OVERVIEW

Online process monitoring with seelectorICAM LASER

The seelectorICAM LASER quality assurance system reliably checks the strength of the seam and the quality of the welding process during laser remote welding.

The task:

- Laser material processing requires optical monitoring

- Laser processes are very fast and light intensive

- The quality requirements are high

- The cycle times are short

- Laser processing must be economical!

What errors occur?

- Cracks and pores

- Splashes

- Inclusions

- Incomplete welding through (false friends)

The answer:

Greater precision and economy in laser welding with seelectorICAM LASER

- Quality assurance system integrated in the laser system, 100% control

- Intelligent cameras with embedded computer on board

- Quick evaluation within the production cycle, 100% inline capable

- High brightness dynamics for strong image contrasts

- Extremely short startup

- Comfortable user interface

- High reliability with low service

- Greatest profitability

- Proven process at Mercedes-Benz Group AG

SPECIAL FEATURES

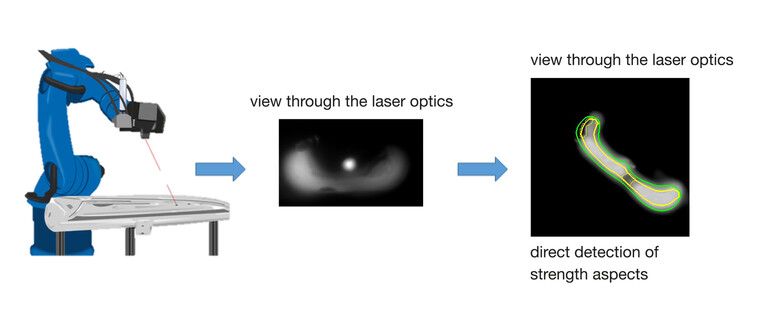

Inline quality assurance in the process - not downstream!

Quality assurance in laser material processing presents a special challenge. There are no measured values at the welding point that can simply be recorded and provide a statement about the success of the weld. Welding control can therefore only be performed optically. The seelectorICAM LASER quality assurance system provides the user with a reliable fully automatic inspection system.

seelectorICAM LASER for steel

The previous images are evaluated parallel to the subsequent welds and image acquisition. We inspect the overlap seams created by the laser between two steel sheets of different shapes and lengths.

seelectorICAM LASER for aluminum

The seams are welded through to the visible seam root. The through-weld is inspected on the reverse side and can be smoothed if necessary. The evaluation is also carried out parallel to further processing.

The intelligent camera, coupled into the laser optics, looks at the process and checks the quality of the seam just welded. It transfers its inspection result to the system control. This immediately releases the welded part or ejects it.

Laser remote welding in car body production thus becomes 100 percent controllable and reliably suitable for series production. More than 160 systems are already in use by vehicle manufacturers and prove their worth every day.

Extremely short startup, comfortable user interface and extensive service functions convince our customers.

APPLICATIONS

Laser remote welding in car body construction

We find reliable:

- missing connection

- poor lasering

- holes and tears in the weld seam

We assess reliable:

- the strength of the weld

- the quality of the welding process

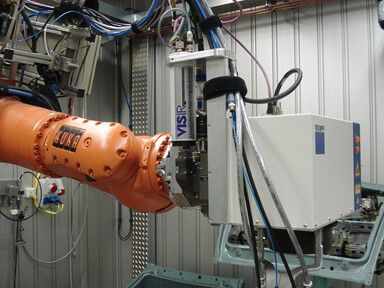

hema camera system seelectorICAM LASER on Blackbird intelliWELD system

hema camera system seelectorICAM LASER on Trumpf 3D PFO system